He' Nan Chineng Electric Power Equipment Co., Ltd

Contact Us

SC(B)18 Stacked Core Dry Type Transformer,Cast coil dry-type transformer

Products Category

Keyword

SC(B)14 Stacked Core Dry Type Transformer

Cast resin transformer

Cast coil dry-type transformer

Details

In the ever - evolving field of electrical power distribution, the Cast coil dry-type transformer has emerged as a significant innovation, offering a host of advantages for various applications.A Cast coil dry-type transformer is designed with a unique construction method. The coils are cast using high - quality insulating materials, which provides excellent electrical insulation properties. This casting process ensures that the coils are firmly held in place, enhancing the mechanical stability of the transformer.

One of the key benefits of the Cast coil dry-type transformer is its high - efficiency operation. It is engineered to minimize energy losses during the power conversion process. This not only reduces the overall energy consumption but also contributes to cost savings for users in the long run. With the increasing emphasis on energy efficiency in today's world, this feature makes the Cast coil dry-type transformer an attractive choice for both industrial and commercial applications.

The dry - type nature of this transformer is another important aspect. Unlike oil - filled transformers, the Cast coil dry-type transformer does not require oil for insulation and cooling. This eliminates the risk of oil leakage, which can be a significant environmental and safety hazard. It also makes the transformer more suitable for installation in indoor environments where oil - based transformers may not be allowed due to fire and safety regulations.

In terms of reliability, the Cast coil dry-type transformer has a proven track record. The solid construction of the cast coils can withstand a wide range of electrical and mechanical stresses. This makes it highly resistant to short - circuits and other electrical faults. Additionally, its design allows for better heat dissipation, which further enhances its durability and performance over time.

The compact size of the Cast coil dry-type transformer is yet another advantage. It takes up less space compared to some traditional transformers, making it ideal for applications where space is at a premium. This is especially beneficial in urban areas or in industrial facilities where available floor space is limited.

Manufacturers are constantly improving the design and performance of Cast coil dry-type transformer. They are incorporating advanced technologies such as better insulation materials and more efficient cooling systems. These improvements are aimed at further enhancing the transformer's efficiency, reliability, and safety.

The Cast coil dry-type transformer also has a wide range of applications. It can be used in industrial plants, commercial buildings such as shopping malls and office complexes, and in power distribution substations. In industrial settings, it can provide the necessary power conversion for various types of machinery and equipment. In commercial buildings, it ensures a stable and efficient power supply for lighting, heating, ventilation, and other electrical systems.

In conclusion, the Cast coil dry-type transformer is a reliable, efficient, and versatile power - handling device. Its unique features and advantages make it a preferred choice for many electrical power - related applications, and it is expected to play an increasingly important role in the future development of the power industry.

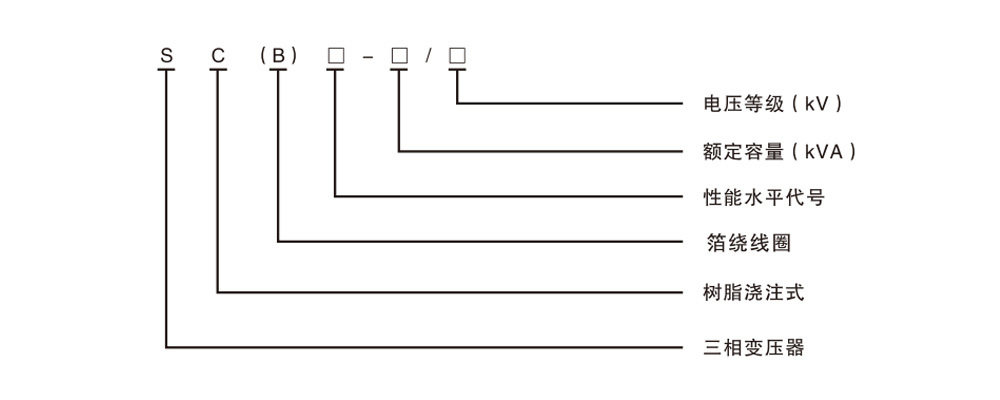

Type and meaning

Product Overview

SC(B) dry-type transformer is made of F-class environmentally friendly epoxy resin casting under vacuum, which is a kind of dry-type transformer with high mechanical strength, electrical strength and heat-resistant strength. It is the first choice of urban power grid renovation, especially suitable for high-rise buildings, airports, power stations, commercial centres and other important places that require fire, explosion-proof and moisture-proof.

Product features

explosion-proof, explosion-proof, pollution-free, maintenance-free, low noise, low loss and so on.

The shell is made of stainless steel or aluminium alloy, and the way of inlet and outlet can be taken as follows: top inlet and outlet, bottom inlet and outlet, and bottom inlet and outlet.

Executive standard

2.1 IEC60076 dry-type power transformer 2.2GB1094.1 power transformer

2.3GB1094.11 dry-type power transformer

2.4GB/T10228 dry-type power transformer technical parameters and requirements

2.5JB/T10028-20046KV-500KV level power transformer sound level

2.6GB20052 power Transformer

Performance parameter table

| Model number | Rated capacity (KVA) | Link Group Label | Voltage combination (KV) | No-load loss(W) | Load Loss(W) (120℃) | No-load current (%) | Short circuit impedance (%) |

||

| Oppressive | Scope of decomposition | Undervoltage | |||||||

| SC14-30 | 30 |

YynO |

10 |

±5% |

0.4 |

130 | 640 | 2.0 |

4.0 |

| SC14-50 | 50 | 185 | 900 | 2.0 | |||||

| sC14-80 | 80 | 250 | 1240 | 1.5 | |||||

| S014-100 | 100 | 270 | 1415 | 1.5 | |||||

| sC14-125 | 125 | 320 | 1665 | 1.3 | |||||

| SC14-160 | 160 | 365 | 1915 | 1.3 | |||||

| SCB14-200 | 200 | 420 | 2275 | 1.1 | |||||

| SCB14-250 | 250 | 490 | 2485 | 1.1 | |||||

| SCB14-315 | 315 | 600 | 3125 | 1.0 | |||||

| SCB14-400 | 400 | 665 | 3590 | 1.0 | |||||

| SCB14-500 | 500 | 790 | 4390 | 1.0 | |||||

| SCB14-630 | 630 | 910 | 5290 | 0.85 |

6.0 |

||||

| SGB14-630 | 630 | 885 | 5365 | 0.85 | |||||

| SCB14-800 | 800 | 1035 | 6265 | 0.85 | |||||

| SCB14-1000 | 1000 | 1205 | 7315 | 0.85 | |||||

| SCB14-1250 | 1250 | 1420 | 8720 | 0.85 | |||||

| SC814-1600 | 1600 | 1665 | 10555 | 0.85 | |||||

| SCB14-2000 | 2000 | 2075 | 13005 | 0.7 | |||||

| SCB14-2500 | 2500 | 2450 | 15445 | 0.7 | |||||

Online Message

Recommend Products